Getting ideas for products is hardly ever about reinventing the wheel. It’s more of adding my spin to what already exists. Sometimes, the idea for a product comes from a personal need or simply having conversations with people.

As a person who’s also fascinated by objects and design, I spend a lot of time reading journals on related subjects. I also get into a wormhole (or two) on websites like Pinterest and Etsy.

I am obsessed with good design – every kind of design – architecture, urban, interior, furniture and everyday things. When I watch movies, I look at the set, the colours, the landscape, the costumes of the actors; everything.

The idea for a watch strap struck me when the rubber strap on my current piece broke, and I needed a replacement. I could have easily bought and fixed another one, but I had encountered handmade leather straps on Pinterest during my routine browsing and pinning. I just knew I wanted one for myself. Leather feels very natural, and it feels better as it ages. So I reached out to our leather artisan, sharing with him what I wanted. He understood the assignment because he had also made some straps in the past.

My new leather strap came in after about three weeks. I took a photo of it and shared it on Twitter, Instagram and WhatsApp stories. It caught some people’s attention and three people reached out regarding leather straps for Apple watches. That was when I knew I had to work on a prototype, but I didn’t own an Apple watch. Luckily, another person saw my new leather strap in person and immediately fell in love with it. A fascinating part of my leather strap is an extra leather pad under the watch head. He had an Apple watch, and he wanted a similar treatment for his piece. I mentioned to him that this would be the first one ever and might come with some imperfections. He was willing to have it nonetheless.

The first prototype was officially in the pipeline.

I pulled references from Etsy and Pinterest, made some iterations, and shared them with our leather artisan. It came with challenges; for example, we had to figure out a way to cut an opening in the leather pad under the watch head so the sensors could make contact with the skin.

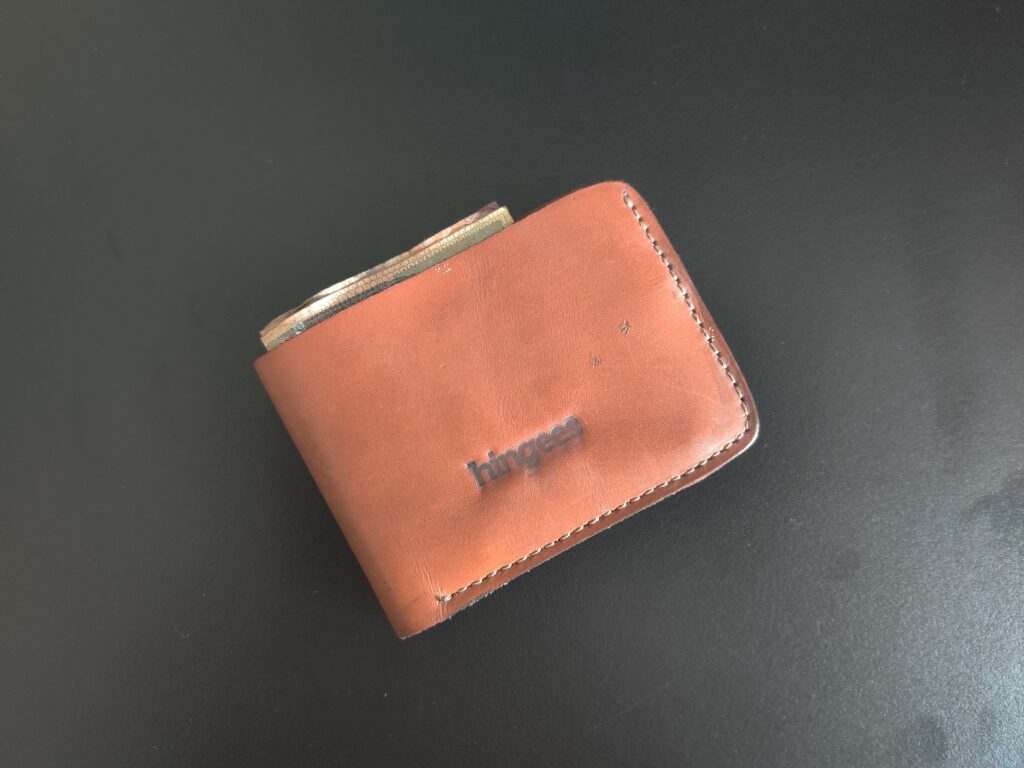

The prototype/iteration phase in every product development is challenging and exciting. For example, when we were making prototypes for our bifold wallet two years ago, we wanted a simple, flat, and functional wallet with the capacity to hold enough cash. The size of debit and credit cards is universal, but the size of money bills is not. Our target was Nigerian customers, and so, we cut the first prototype in the exact size of the big Naira bills (₦100, ₦200, ₦500, and ₦1,000). However, there was a flaw in the design. After stitching and putting the wallet together, the bills didn’t sit entirely in the cash compartment. The edges of the bills were sticking out.

We had to fix it, meaning the wallet would be slightly bigger than we initially imagined. After two more iterations coupled with material testing, we got it right! The bi-fold wallet launched four months after the first sample. It was our best-selling product at the time – it sold out multiple times.

. . . .

As the first Apple leather strap progressed, we finally found a way around making an opening in the underpad. However, rather than having a perfect circle opening, we opted for a square. It was a lot easier to achieve compared to a circle. The wristwatch strap was ready in three weeks, and I shipped it to the owner. He was very delighted and promised to share feedback after using it for a while.

. . . .

Meanwhile, we set things in motion to place orders for hardware (connectors and custom buckles). Our manufacturers in China usually take five to six weeks to get the accessories down to Nigeria.

Before the final production of anything, we test for quality, ease of use, functionality, and durability. In the case of leather goods, we want to know how much it expands and contracts with time and the ability to absorb or repel liquid. We already got a hang of the kind of leather we use for our products so we didn’t need to test for that. It’s full-grain vegetable-tanned leather – the outermost layer of the hide that hasn’t been sanded or buffed to eliminate any flaws. Full-grain leather is highly valued for its natural grain and texture, giving it a unique appearance and a beautiful patina that develops over time.

For other items like apparel, after test prints, we do a machine wash with some harsh settings to be sure the prints won’t easily give way over time.

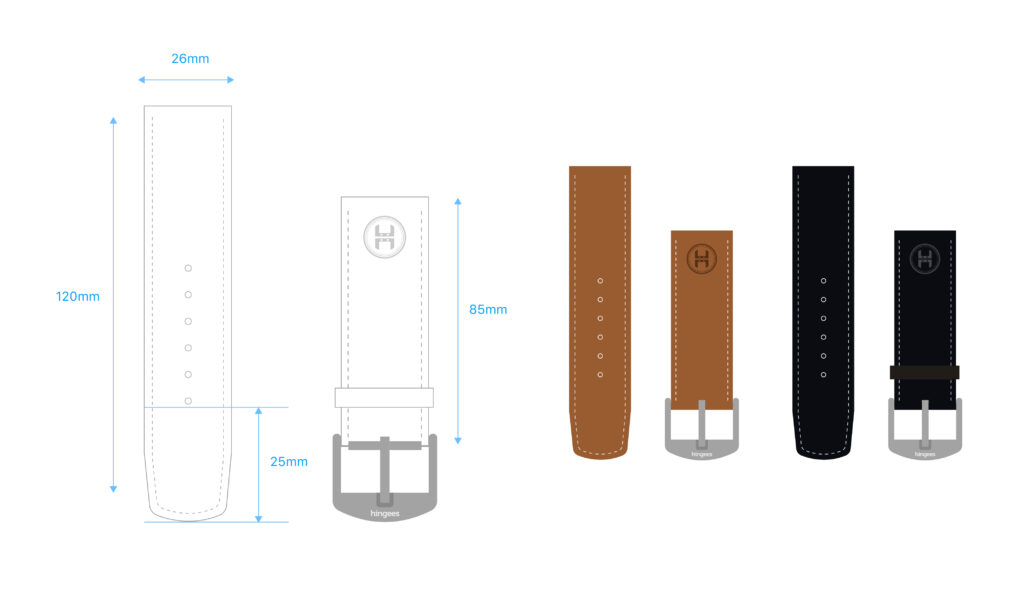

In the case of the leather straps, the whole point is to see how they develop a cool patina as they age. The hardware showed up on time, and they looked decent. But, there was a little issue: the buckle turned out to be a tad bigger than I expected. It just didn’t look right compared to the popular Apple watches (42, 44, and 45-inch ones). This was my first time ordering this kind of hardware from this supplier, so I needed to learn more about buckle sizes. So, I researched and talked to our artisan to figure out the correct size. Once we nailed it down, I placed another order.

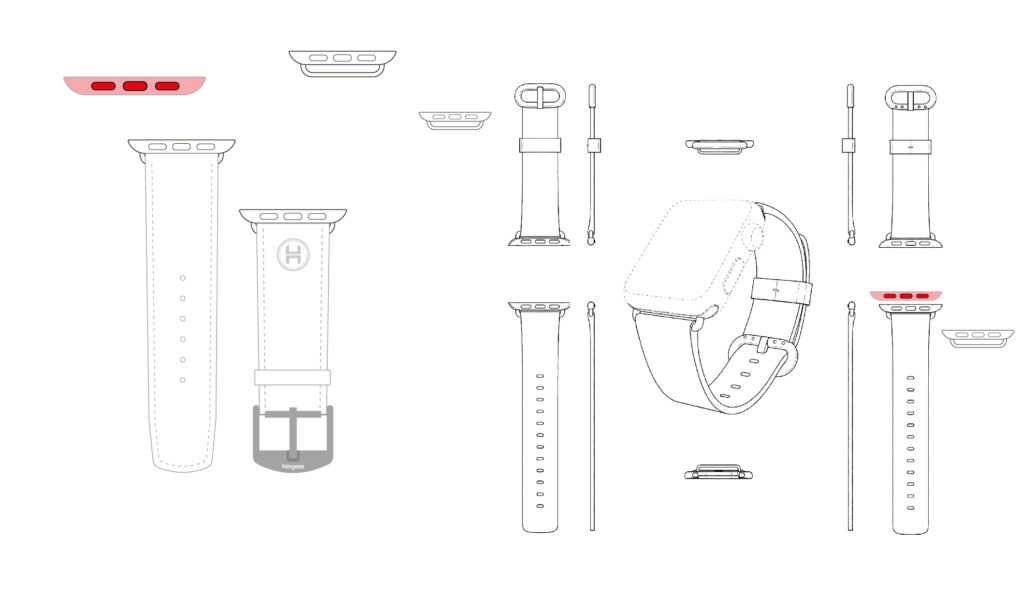

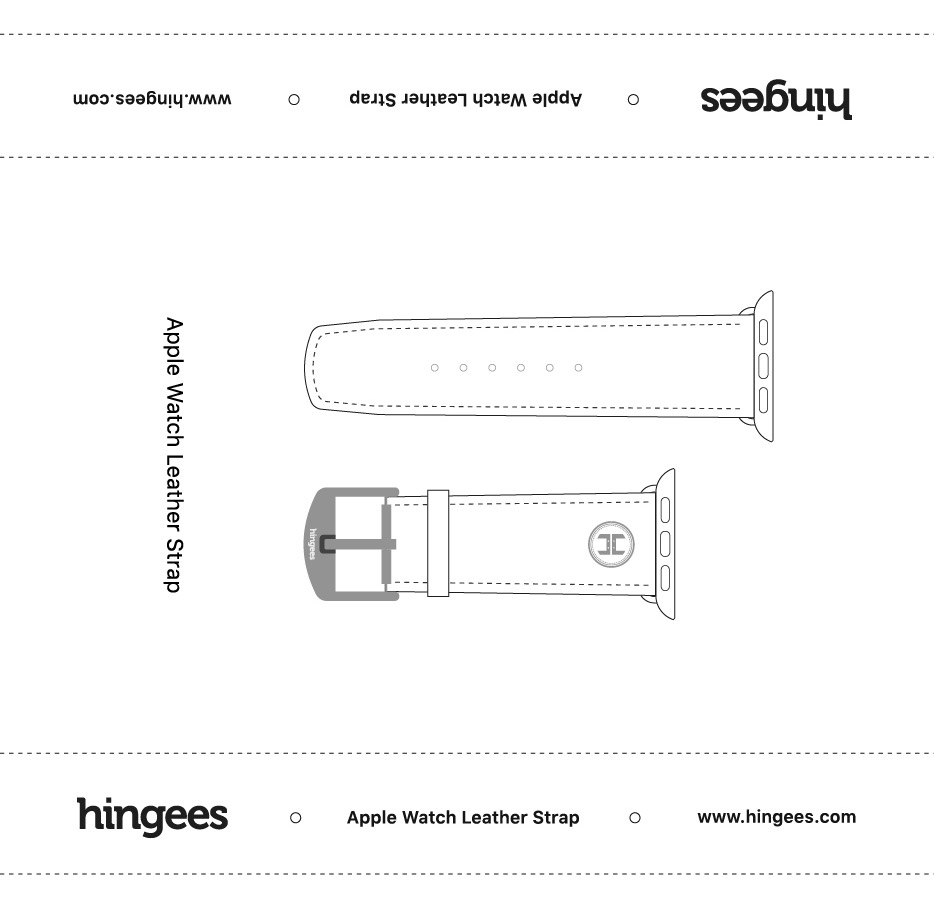

While that was in progress, I decided to take things up a notch. I had a clear vision of how I wanted the straps to look, so I gathered some references and fired up Adobe Illustrator to begin the creation process. Sometimes, I get so pumped on days like these that I can’t resist skipping the pen and paper step.

. . . .

I sent the final design to our artisan, and got positive feedback: it was possible to get the exact cut.

We waited for a couple of weeks to receive the new hardware, and when it finally arrived, it was the perfect size. And then, we decided to make another prototype, this time, with my updated design. It came out good, and I knew we were onto something.

At this time, I began contemplating our product’s most effective packaging design. I had two choices: get a pre-made package from China or create something entirely new using local materials and artisans. Considering that we were developing a product for Apple, it was crucial for the packaging to align with their brand and provide the right experience. I delved into blogs discussing Apple’s approach to packaging design to gain insights and scoured numerous websites for inspiration.

Production costs were also a significant factor to consider in all of this. So, I spent some time with my guys in Shomolu to discuss the options. After several deliberations, we concluded that a simple matchbox concept would be the ideal and most cost-effective approach for this project.

. . . .

To give the packaging a more premium feel, we paired it with polyurethane foam inserts, allowing the straps to sit perfectly in the box. We made a few samples before getting the perfect die-cut.

While production of the new straps was in progress, we also set things in motion for bulk roll out of the packaging box. It all came together nicely after about three weeks.

Next was to figure out photography. It was such an incredible feeling to hold the completed watch straps in my hands finally. I mean, they looked and felt incredible in person! But here’s the thing: I wanted to ensure that the same level of quality and attention to detail would shine through in the product photography. You know, many people overlook this crucial aspect when selling stuff online and skimp on photography.

I spent several days on Pinterest, scouring through watch photography and creating a mood board. After that, I shared it with a friend who runs a photography studio called Studiomaz. We decided on a day, and I went to his studio in Surulere.

We spent several hours photographing the wristwatch strap and other Hingees products. It all turned out nicely.

. . . .

. . . .

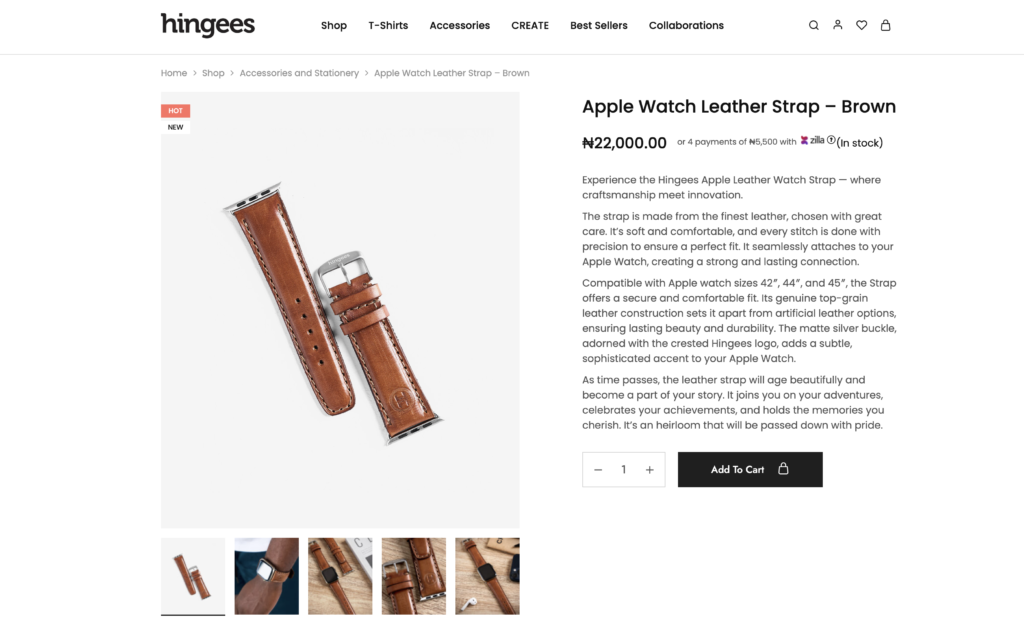

After working on and off for 13 months, it was such a great feeling to finally flip the switch and launch the watch straps in our shop. I always wonder how people will respond to a new product. We launched the Apple watch straps alongside five other amazing new products.

I was thrilled when the first batch of straps almost sold out in just three weeks, with people asking for other sizes!

Throughout this process, I’ve learned so much, including the importance of patience. I’m excited to apply this newfound knowledge to future products.

This gives you a glimpse into what goes on behind the scenes in making things at Hingees.

You can get the Apple Leather Watch Strap here

. . . .

Comments (4)